We have some exciting news to share…

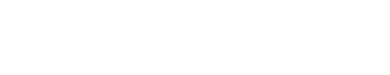

After electronics manufacturers assisted with the development of cutting-edge fire-fighting devices like drones and robots to control wildfires last year, many organisations sought to bring the safety benefits of tech-driven products closer to home in 2024. EMS helped one of these organisations — Prefect Controls — do just that with the new HobSensus, which prevents the outbreak of accidental fires in university halls.

Why is Prefect Controls’ device so important, how does it work and what role did we play in ensuring it was built to the highest possible standards? Find out below.

Protecting students from an alarmingly common incident

Whilst some students regularly cook after an alcohol-filled night out, others may be more careful — but simply lack experience in the kitchen. As a result, halls residents can easily make a plethora of dangerous mistakes at mealtimes.

Research from Electrical Safety First found that:

- One in seven students, the equivalent of almost 300,000, had fallen asleep with food cooking.

- Over half of students admitted to cooking whilst drunk or after drinking.

- One in four students were guilty of putting a knife or fork into a toaster.

- A fifth said they’d misused the microwave — either for fun or by mistake — by putting something inside it that shouldn’t be put in a microwave.

- Almost three quarters confessed they’d been distracted whilst cooking food, subsequently leaving it unattended.

All this can (and often does) lead to fires. In fact, the problem of fires in university kitchens is so bad that from 2015–2020, London firefighters attended 1,262 fire-related incidents at universities, with over 90% of these fires being caused simply by unattended cooking or overdone toast.

Having supplied energy controls for student accommodation providers for decades, Prefect Controls aimed to do something about this issue with a new intelligent sensor-based device that monitors the temperature across 64 zones on the cooking surface.

HobSensus triggers flashing amber lights and a beeping sound if temperatures exceed 250 degrees Celsius and cuts off the power to the hob if temperatures reach 290 degrees Celsius — or if it’s on for longer than the time set on its built-in timer (which has options of 15, 20, 30 and 120 minutes).

This device can also be connected to smoke and fire alarms and call a designated number to inform the receiver the unit’s been triggered.

Manufacturing a fail-safe product

Prefect Controls knew that a product this innovative would require expert electronics manufacturing solutions to function properly and safely. Which is where EMS came in…

As a global electronics manufacturing services provider with experience across many sectors, including energy and building controls, Prefect Controls enlisted our support from a design-for-manufacturing point of view.

With the help of Ben Mack at Designerds, our experts handled everything from the integrated heat sensors and timers used for the HobSensus to its packaging, whilst also developing prototypes and conducting numerous tests to minimise the risk of errors.

We also made sure our supplier ProPlastix produced the relevant mouldings in polycarbonate/acrylonitrile butadiene styrene (PC-ABS), which is fully UV stable and resistant to cleaning products. The final product was then finished with a gloss overlay for easy cleaning and tamper-proofed to ensure meddling students couldn’t interfere with its effectiveness.

And the results speak for themselves, as the HobSensus was granted the Safety Innovation Award 2023 at last year’s annual Electrical Safety First (ESF) conference!

The event panel noted that HobSensus was tested and approved to BS EN50615 Category B whilst praising its robustness and ability to identify patterns of risk, be affordably retrofitted into existing installations and integrated with other fire systems. They also commended the fact it’s targeted to higher-risk installations.

We’re thrilled to have helped Prefect Controls gain recognition from such a prestigious institution. The award speaks volumes about the power of HobSensus to make university halls safer and fills us with confidence that it’ll soon appear in kitchens everywhere!

Interested in working with EMS on your upcoming project? We offer a range of electronics manufacturing services; speak to a member of our team at +44 (0)1635 588 871 or email sales@emsolutions.uk.com to learn more.